-

Shelf with inbuilt foldable desk in narrow hallway

-

Pendulum Print Bot

Concept A servo driven pendulum gets a robot swinging attached to an anchor via a cable winch on any canvas. A 2-axis canvas is created which could scale to any size of canvas with the only expense of the cable while only one anchor needs to be attached to the canvas. Indoor (whiteboard) and Outdoor…

-

Laser Cutting Business Cards

-

Good News Everyone: Typewriter fully functional.

After many hours of work, my typewriter is now fully functional and printing your tweets. Check it out at http://lepetiteprintshop.com/ At the time of writing this, it actually already printed 68 tweets from all over the world. However, since this is a project that will probably never be 100% done, here are my upcoming optimization tasks:…

-

Typewriter to Printer: Setbacks & Progress

I totally forgot that just having a web video stream of what is happening on the typewriter is not enough. What if actually a few people want to watch it at the same time? Bummer, have to investigate that. So far tests showed not even enough frames come out of that android IP cam app…

-

Typewriter to Printer Conversion, Update (getting close)

Good News Everybody. The typewriter (actually the raspberry pi) is now capable of picking up print jobs from my typewriter API. See yourself in the following video. For now I just use a web interface to add the jobs manually but soon the jobs will come in from twitter via a hashtag or tweets towards the…

-

Typewriter to Printer

A python script on my Raspberry Pi is now typing on my typewriter, not optimized yet, but working. Yeah! zzzzzzzzzzzzzz

-

Typewriter to Printer: Software Update

I am turning an almost hundred year old typewriter into a Twitter printer. An update is needed here, since a few things changed, not as much progress as wanted was done though. I decided for the future of the project to use a Raspberry Pi to operate the typewriter and the connected webcam. Why? Arduino…

-

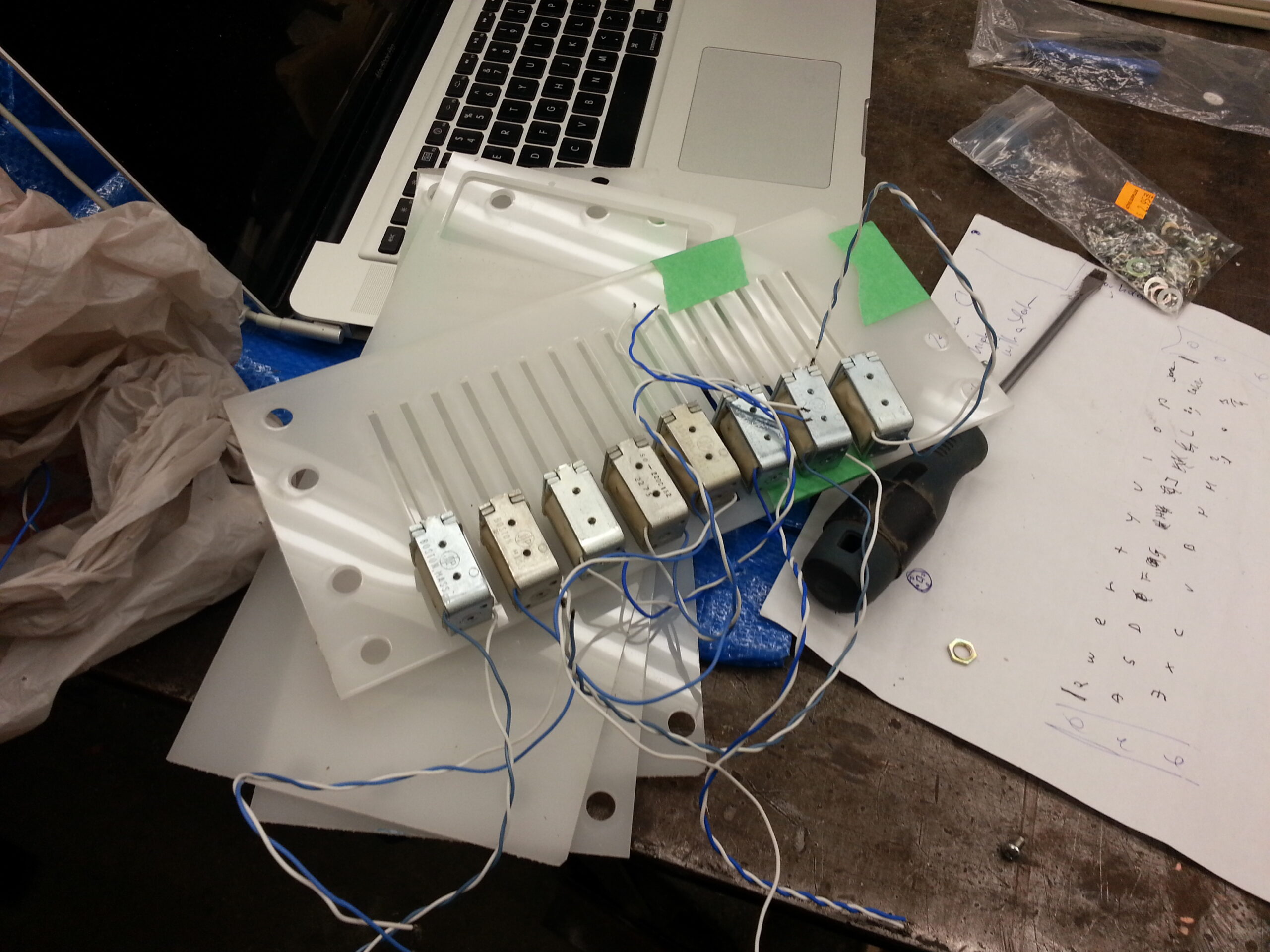

Typewriter to Printer: Progress!

I am converting an almost 100 year old typewriter into a printer that will print your tweets to it on paper while you can watch it on a webcam. It has been a good week for the typewriter to printer conversion project. Andrew helped me put together a table I designed for the typewriter.…

-

Time-Lapse Cube

Remember those really cool time-lapse videos on educational kids TV about how a seed started growing? Things moving too slow for us to recognize in our fast pace. Last summer I tried to capture a day of the city of Toronto by using a web cam and fast forwarded it later. First try. However, I am…